Watch manufacturing

Save time, reduce errors and optimize your logistics flows

Watch manufacturing involves the management of thousands of spare parts, for hundreds of models of watches. This logistical complexity makes manual inventory time-consuming, leading to storage errors and considerable lost time in the search for components.

With the Centiloc solution, you have access to real-time traceability and an instant location of all your parts, thanks to NFC technology and our NFC readers.

The concrete benefits for watchmakers

- Precise and instant location of components. Each part is automatically identified and located, without human intervention. You drastically reduce search times.

- Continuous automated inventory. No more long and tedious manual counting: your inventory is updated in real time, without interrupting your operations.

- Fewer errors, fewer losses. The precision of NFC makes your processes safer: reduction of picking errors, omissions or losses of valuable components.

- Full traceability of movements of parts. Access the position history, identify parts via their UID, and integrate all data via our ERP-compatible API.

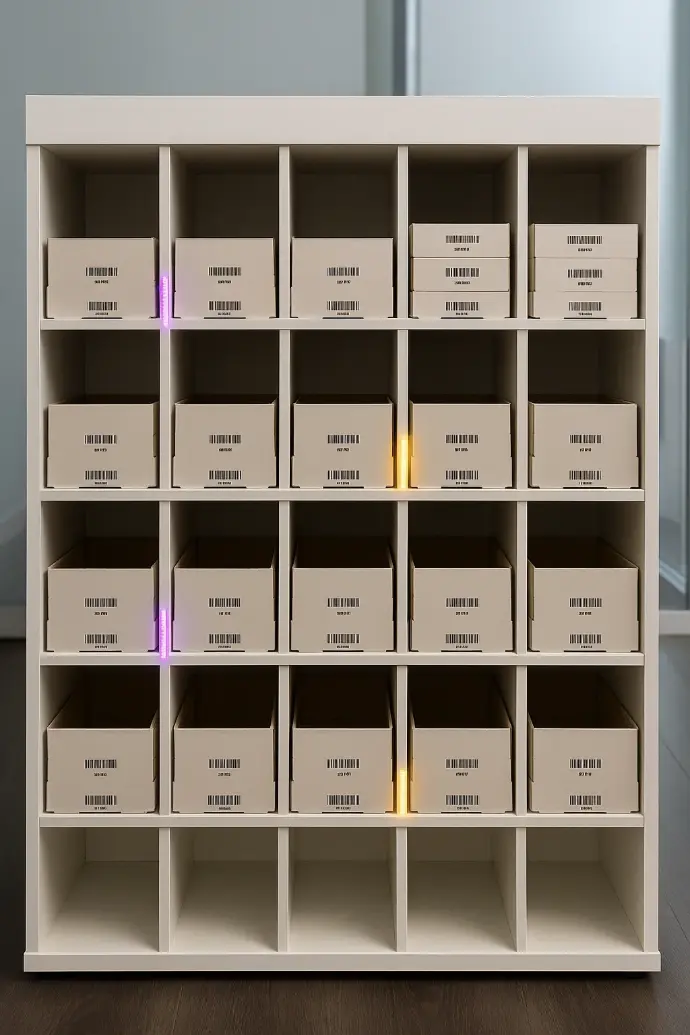

Pick-to-Light :

Find the right parts instantly

Thanks to our technology integrated into the storage units, each room is identified, located and connected to your ERP system.

When the operator selects a watch model on its interface, the boxes containing the necessary components light up automatically.

This Pick-to-Light system allows:

- Assemble faster by removing manual searches.

- Reduce coin picking errors.

- Speed up production flows while making each step more reliable.

This solution combines traceability and intelligent visual guidance, for a smooth, precise and optimized logistics.

Also discover: