Traçabilité

Lutte contre le marché parallèle

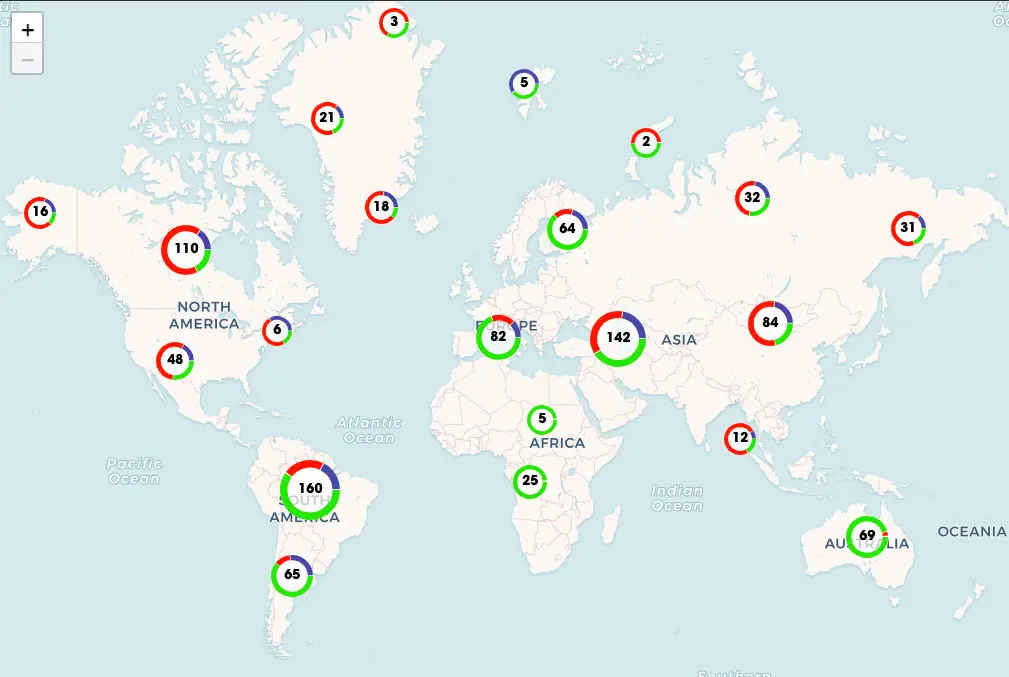

Reprenez le contrôle sur vos produits, partout dans le monde

Suivez vos produits avec précision, à chaque étape de leur parcours.

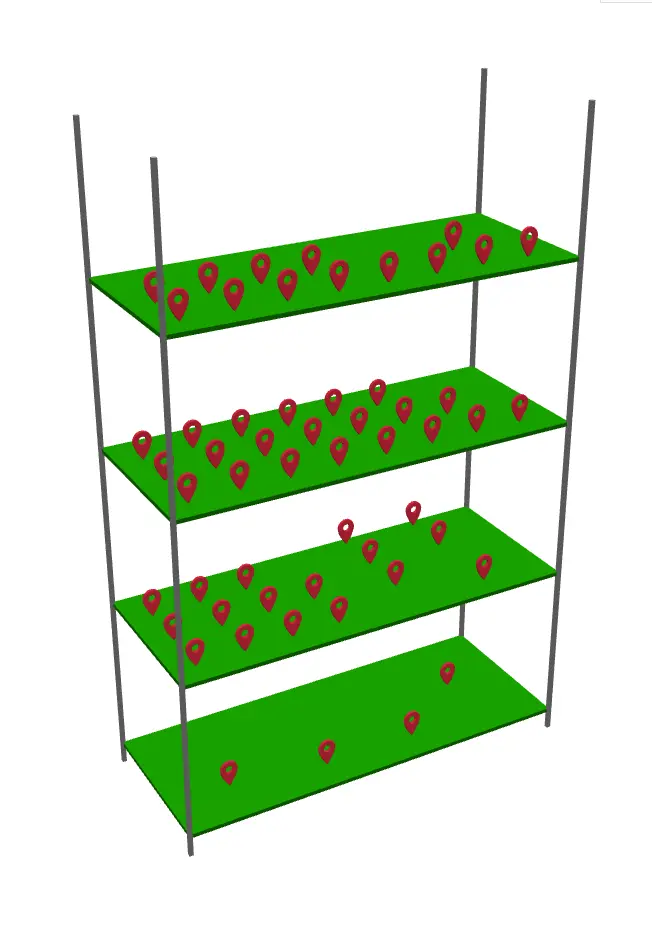

Centiloc vous permet de tracer chaque article en temps réel, de la mise en rayon jusqu’à la vente. Vous gardez la maîtrise sur votre réseau de distribution, identifiez les anomalies et garantissez la conformité de vos opérations.

Renforcez la confiance et la conformité

Grâce à une traçabilité claire et accessible, vous renforcez la transparence vis-à-vis de vos distributeurs et partenaires. Vous garantissez le respect des conditions de distribution, améliorez vos process logistiques, et assurez une gestion rigoureuse de vos stocks.

Une visibilité totale sur vos circuits de distribution

Notre technologie vous offre une vue précise sur l’emplacement de chaque produit. Vous savez où il est, s’il a été déplacé, et s’il est bien présent dans le point de vente prévu. Cette transparence vous permet de détecter les écarts rapidement et d’agir sans délai.

Lutte contre le marché parallèle

Sécurisez vos flux, protégez votre marque.

Le marché parallèle ou marché gris fragilise les marques en permettant à certains produits de sortir du circuit de distribution prévu, avec des impacts directs sur les marges, la stratégie tarifaire et l’image globale. Pour y répondre, Centiloc propose une solution concrète et innovante, basée sur une traçabilité fine et dynamique.

En installant des lecteurs NFC à l’entrée de vos entrepôts, plateformes logistiques ou magasins, vous êtes en mesure de contrôler automatiquement la conformité du flux physique. Si un produit transite par un lieu non reconnu, une alerte est immédiatement générée. Cela vous permet d’intervenir rapidement, de détecter les écarts et de suivre précisément la circulation de vos articles.

Grâce à notre technologie NFC, chaque produit peut être équipé d’un tag enrichi contenant des informations essentielles comme sa destination finale ou les points de passage logistiques qu’il doit respecter. Ces données sont cryptées directement dans le tag, ce qui permet une vérification fiable à chaque étape du parcours.

Grâce à notre technologie NFC, chaque produit peut être équipé d’un tag enrichi contenant des informations essentielles comme sa destination finale ou les points de passage logistiques qu’il doit respecter. Ces données sont cryptées directement dans le tag, ce qui permet une vérification fiable à chaque étape du parcours.

Cette solution vous aide à identifier les détournements, à réduire significativement les ventes hors réseau, et à sécuriser l’ensemble de votre chaîne de distribution. En gardant la main sur vos flux, vous garantissez le respect de vos stratégies commerciales et assurez à vos clients une offre maîtrisée, cohérente et conforme à vos standards de qualité.

Tapping RFID-NFC grâce au smartphone

Chaque produit équipé d’un tag NFC peut être scanné simplement à l’aide d’un smartphone compatible. En un "tap", les informations stockées dans le tag comme la destination prévue ou les points de passage sont immédiatement lues et transmises vers votre ERP.

Cette fonctionnalité permet de vérifier, à tout moment et en tout lieu, que le produit se trouve bien dans le bon circuit de distribution. Un outil efficace pour lutter contre le marché gris et garantir une distribution conforme aux canaux définis.