Anticipez les ruptures

Avec une visibilité continue sur vos rayons, vous détectez les manques instantanément. Vous agissez avant que la rupture n’impacte vos ventes.

La fin des inventaires manuels

L’inventaire est automatisé, mis à jour en temps réel, sans intervention humaine.

Vous gagnez du temps, réduisez les erreurs et libérez vos équipes.

Vue à distance en temps réel

Suivez vos stocks magasin par magasin, même à distance.

Une gestion plus fluide, plus réactive, parfaitement maîtrisée.

Gérez vos stocks à distance, en toute simplicité

Vos rayons de demain

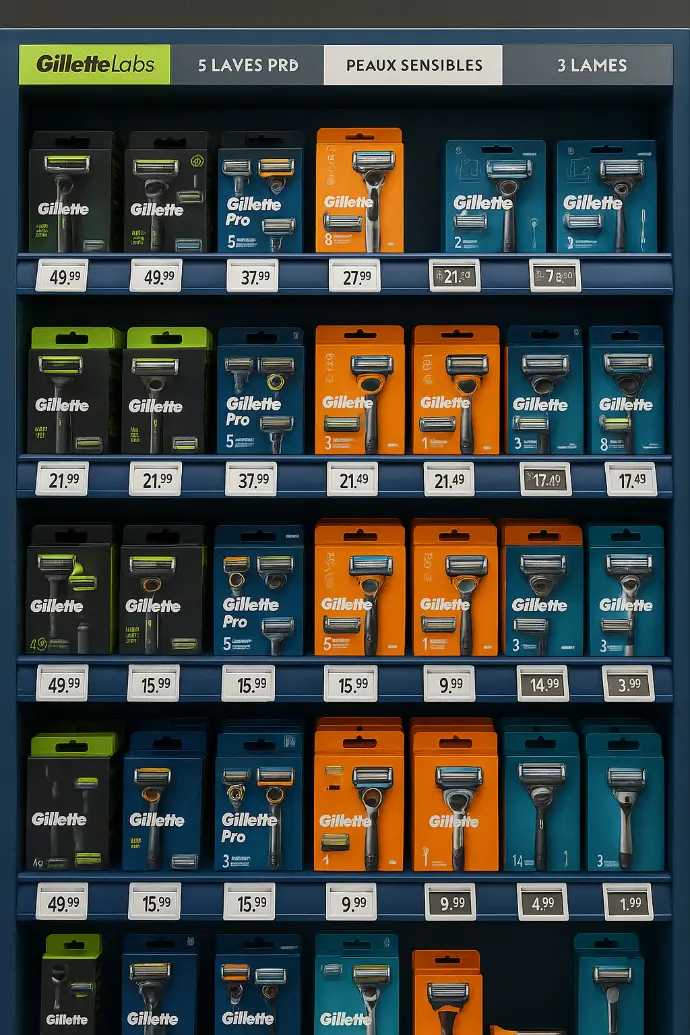

- Respect du planogramme

Notre solution vous permet de vérifier le respect du planogramme. Chaque produit est à sa place, comme prévu par vos équipes merchandising, pour maximiser la visibilité et les ventes.

- Analyse des données produit

Vous accédez à des données précieuses sur le comportement des produits : ceux qui se vendent le plus vite, ceux qui sont peu consultés, ou encore les interactions en rayon. De quoi piloter vos décisions plus finement.

- Réduction de la démarque inconnue

La détection rapide des anomalies vous aide à lutter contre la démarque inconnue. Vous sécurisez vos stocks, tout en gagnant en réactivité.

La PLV autonome

Connectée

Connexion via un routeur 4G

Les données peuvent être envoyées au siège en permanence

Permanent ou temporaire

Permet de ranger et d'exposer des produits à la vente pour une promotion, une saison ou du permanent

Sans fil

Branchée sur une batterie - Jusqu'à 6 mois d'autonomie